class 100 clean room definition

Been laundered in a class 100 cleanroom using ultra-filtered water of 045 micron purity and HEPA-filtered air during moisture removal. Class 10000 would have.

Portafab What Is A Clean Room Cleanroom Design Classification

This class is frequently used in labs and hospitals because it is designed to never permit over 100 particles 05 microns or bigger per cubic foot of air.

. Use of filtration systems such as a high-efficiency particulate. A cleanroom or clean room is an engineered space which maintains a very low concentration of airborne particulates. A cleanroom or clean room is a controlled environment typically used in manufacturing processes and scientific research facilities A cleanroom is designed to control contamination by monitoring airborne and surface particles liquid levels and static electricity.

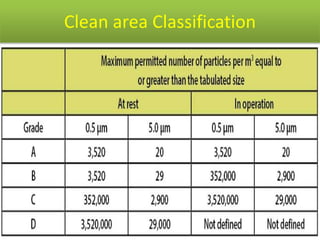

Each Cleanliness Class defined is also assigned a microbial level for air surface and personnel gear. A class 100 cleanroom to a class 10000 cleanroom refers to this kind of working environment. Cleaning solvents can be Di Water a blend of Di Water and Isopropyl alcohol blends cleanroom compatible cleaners and.

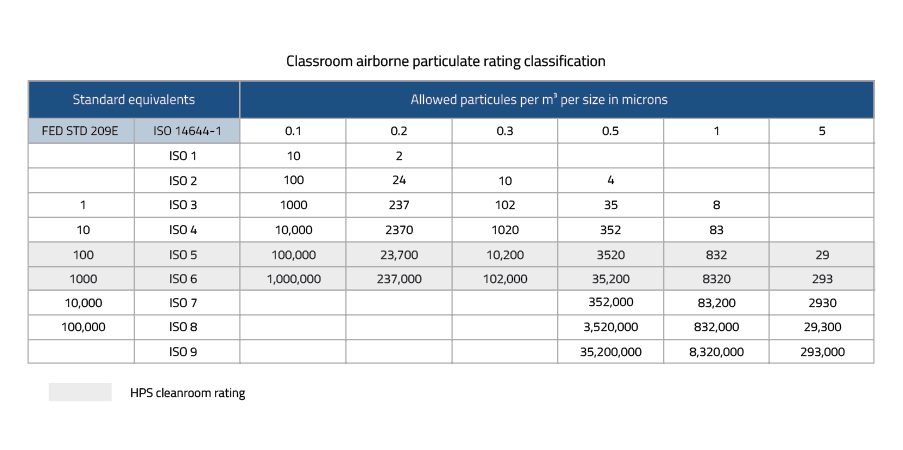

This equates to a Class 100 cleanroom under the Federal Standard 209E which allows for 100 particles 05 microns or larger per cubic foot of air. This artificially created environment is used for specific purposes like scientific research product manufacturing etc. We supply to Europe UK and North America.

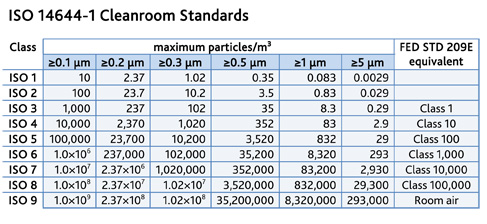

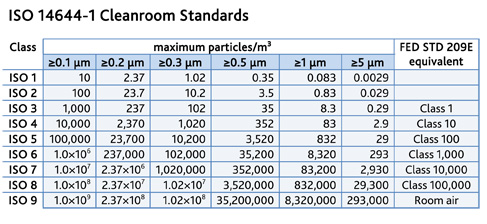

The old Federal Standard 209E FS 209E includes these clean room classes. As an example ISO 8 cleanrooms also known as Class 100000 cleanrooms can be modular or soft-walled. Maintaining a Clean Environment.

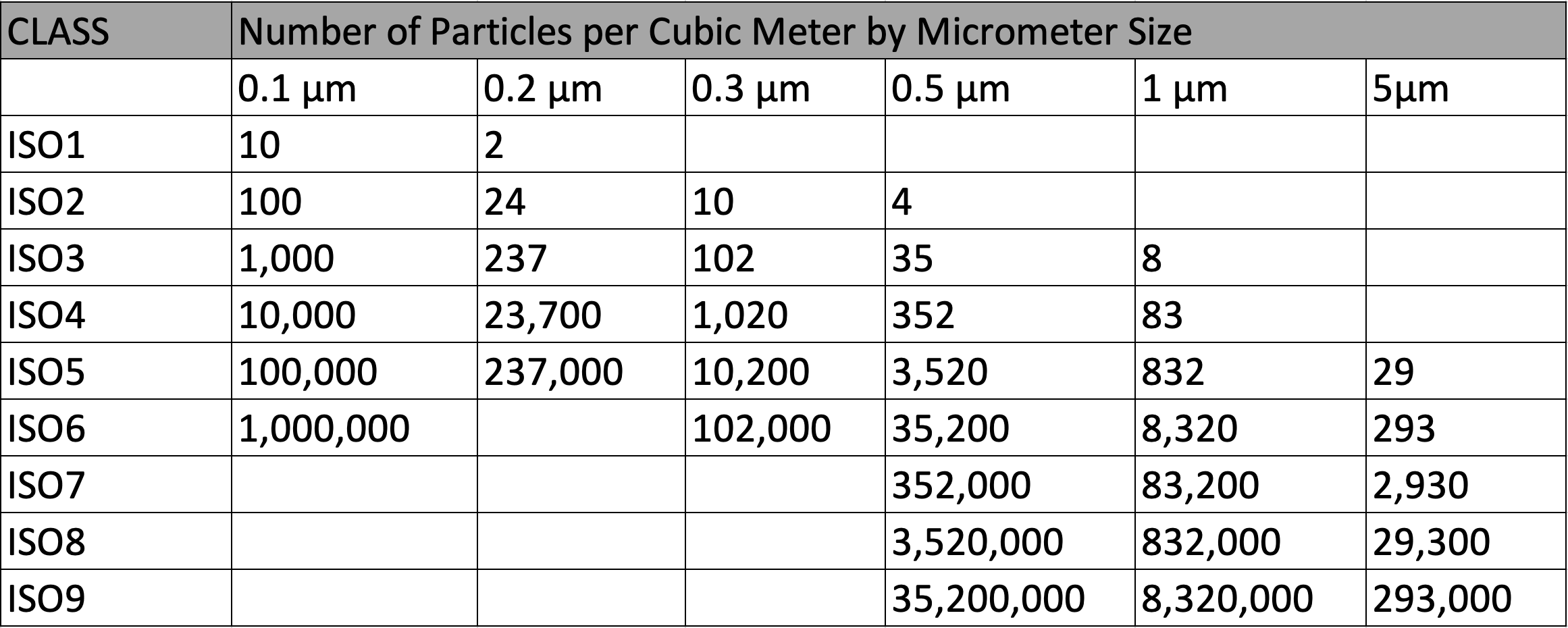

Large numbers like class 100 or class 1000 refer to FED-STD-209E and denote the number of particles of size 05 µm or larger permitted per cubic foot of air. Cleanrooms come in different classes from class 100 to 100000. Class 100 The cleanest room on this list.

Clean Room A room in which the concentration of airborne particles is controlled to meet a specified airborne particulate Cleanliness Class. What is a cleanroom. Cleanrooms are classified according to the number and size of particles permitted per volume of air.

A Class 100 clean room has no more than 100 particles. This near-100 coverage provides a laminar flow of filtered air to quickly remove contaminants from the room thus meeting FS209E standards for Class 10 and ISO Class 1 standards. A Class 100 CLEAN ROOM is a laboratory that has a controlled level of airborne particles and controlled parameters such as humidity temperature and pressure etc.

Such coverage especially in a large cleanroom can lead to higher energy consumption thus increasing costs for both initial construction and ongoing operation. An ISO 6 clean room Class 1000 cleanroom is a soft- or hard-sided wall manufactured structure that utilizes HEPA filtration systems to maintain air cleanliness levels of a maximum of 1000 particles 05 µm per cubic meter of inside air. Grade C with class 10000 M 55 ISO 7 and grade D with class 100000 M 65 ISO 8.

By comparison your typical office space has between 500000 and 1 million particles per cubic foot. A class 100 cleanroom has 100 particles per cubic foot. Abstract A clean room is an environment typically used in manufacturing or scientific research that has a low level of environmental pollutants such as dust airborne microbes.

Temperature humidity and pressure are controlled as necessary ISO-1 p. These classifications are assigned based on the maximum allowable concentration of particles per cubic foot or meter of air. Class 1000 cleanroom filtration system must provide filter coverage of 20-30 and a minimum of.

Such rooms are commonly needed for scientific research and in industrial production for all nanoscale processes such as semiconductor manufacturing. Even if its classified as the dirtiest class the ISO 9 clean room environment is cleaner than a regular room. EU9 pocket filters in at the entrance.

Stellar Data Recovery offers a complete range of data recovery option to. The lower the ISO class the more stringent the requirements for keeping particles and contamination to the acceptable levels of the room class. In addition to particle control the cleanroom is temperature and humidity controlled to 70F 45 RH.

By comparison an ISO class 5 cleanroom is designed to allow no more than 3520 particles equal to or larger than 05 microns per cubic meter of air. B The guidance given for the maximum permitted number of particles in the at rest condition corresponds approximately to the US Federal Standard 209E and the ISO classifications as follows. The Federal Standard 209 FS 209E equivalent for these ISO classes are Class 10000 and Class 100 000.

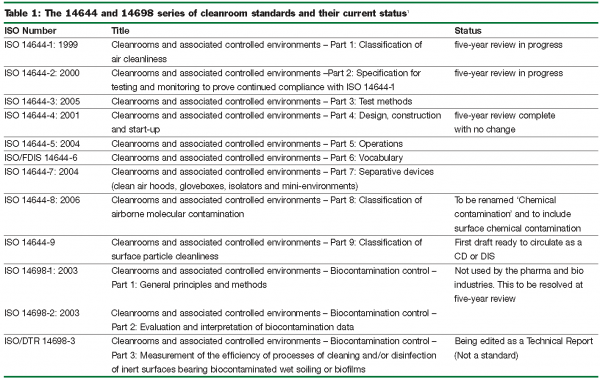

Cleanrooms are classified according to the number and size of particles permitted per volume of air. INTRODUCTION ISO 14644-1 definition of a cleanroomA room in which the concentration of airborne particles is controlled and which is constructed and used in a manner to minimize the introduction generation and retention of particles inside the room and in which other relevant parameters eg. The most common ISO clean room classes are ISO 7 and ISO 8.

A class 100 cleanroom maintains less than one hundred particles larger than 05 microns in each cubic foot of air space. The following are popular classes of clean rooms. Large numbers like class 100 or class 1000 refer to FED_STD-209E and denote the number of particles of size 05 µm or larger permitted per cubic foot of air.

We understand the need for speed and efficiency we cover a wide range of professional cleanroom products. In addition the concentration of microorganisms in the environment is monitored. They look almost like astronaut suits but are not quite as heavy and dont require the large boots for.

The people who work in clean rooms need to wear special suits that prevent them from contaminating the room. Contaminants like airborne dust and other particles can cause failure and waste resources. Modern manufacturing processes and scientific research often require specific very clean environmental conditions.

Room with a defined concentration of airborne particles designed and used in a way that the number of particles introduced into the room or originating and being deposited in the room is as small as possible and in which other cleanliness-relevant parameters such as temperature humidity and pressure can be controlled as required VDI. A cleanroom is designed to keep. Grades A and B correspond with class 100 M 35 ISO 5.

Class 100000 cleanrooms or ISO level 9 rooms also exist. It is well isolated well-controlled from contamination and actively cleansed.

Cleanroom Classification Standards Designtek Consulting Group Llc

What Is A Cleanroom Cleanroom Classifications Class 1 10 100 1 000 10 000 100 000 Iso Standard 14644 Cleanroom Definition

Cleanroom Center For Nanoscale Science And Engineering

An Overview Of Iso 14644 Clean Room Classification Pharmaceutical Guidelines

Understanding Cleanliness Classifications For Life Science Facilities Pharmaceutical Engineering

How To Access Cmi Cleanrooms Center Of Micronanotechnology Cmi Epfl

Inside Our Class 100 Class 1000 Cleanroom High Purity Systems Inc

Cleanroom Classification Standards Designtek Consulting Group Llc

What Is A Cleanroom Angstrom Technology Cleanroom Solutions

Cleanroom Standards European Pharmaceutical Review

Iso 14644 Cleanroom Classification Classes And Requirements

How To Access Cmi Cleanrooms Center Of Micronanotechnology Cmi Epfl

Cleanroom Classification Standards Designtek Consulting Group Llc

Cleanroom Classification Standards Designtek Consulting Group Llc

Understanding Cleanliness Classifications For Life Science Facilities Pharmaceutical Engineering

Inside Our Class 100 Class 1000 Cleanroom High Purity Systems Inc